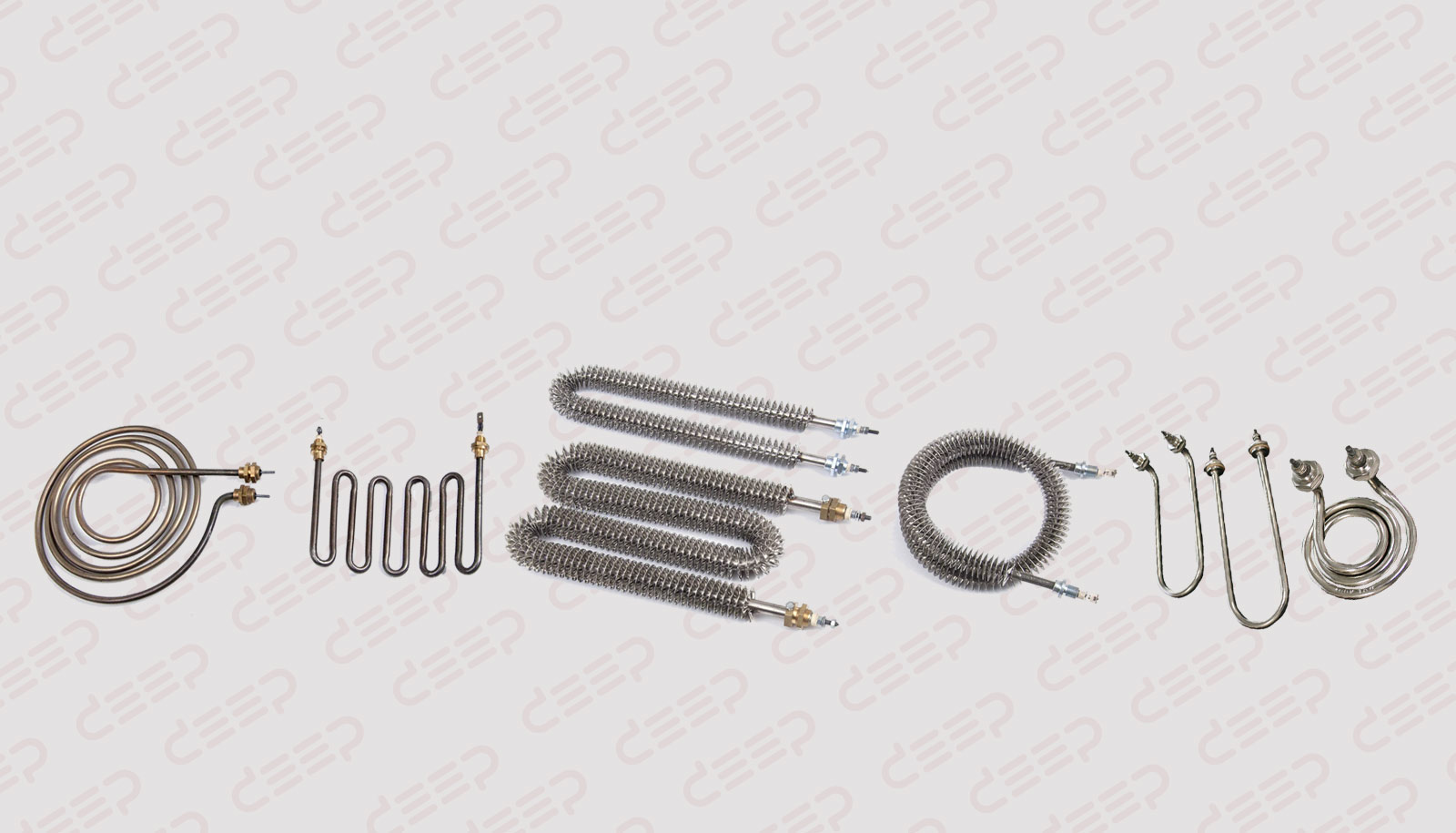

Chemical Immersion Heating Elements

Product Name: Chemical Immersion Heaters

Description:

We offer a wide range of Chemical Immersion Heaters use in corrosive liquids. Selection of heater corrosive solutions heating will depend various factors such as

- 1 pH value of solution to be heated either highly acidic or alkaline

- 2 Selection of sheath tube according to their reactive properties

- 3 Required watt density and specific heat of solution to be heated.

Specification of Chemical Immersion Heaters.

| Category | Watts | Voltage | Depth of Immersion (mm) | Effective Length |

|---|---|---|---|---|

| Alkaline | 2000 | 230 | 525 mm | 335 mm |

| Alkaline | 3000 | 230 | 685 mm | 385 mm |

| Alkaline | 6000 | 230/415 | 900 mm | 650 mm |

| Lead | 2000 | 230 | 525 mm | 335 mm |

| Lead | 3000 | 230 | 685 mm | 385 mm |

| Lead | 6000 | 230/415 | 900 mm | 650 mm |

| Titanium | 2000 | 230 | 600 mm | 450 mm |

| Lead | 3000 | 230 | 900 mm | 750 mm |

Types of Chemical Heaters

Alkaline Immersion Heaters:These are used for most alkaline cleaning solutions normally corrosive to mild steel. These are commonly used in processes like

- Cleaning and Degreasing: Alkaline solutions are commonly used in industrial cleaning applications to remove oils, grease, and contaminants from parts and equipment.

- Metal Finishing: Immersion heaters are used in chemical baths for for cleaning and surface preparation before plating.

- Water Treatment: Heating Elements are used in water treatment processes for pH adjustment or alkalinity control.

- Industry: Alkaline immersion heaters are used in textile manufacturing for processes such as mercerization, which improves the luster, strength, and affinity for dyes of cotton fiber

Lead Covered Immersion Heaters:

Thick layer of lead is covered on stainless steel sheath tube for proctection from corrosion. These heaters are recommended for nickle, copper or chrome plating baths and sulphuric acid solution having not more than 10% concentration. Commonly used in processes like

- Galvanizing Baths: These heaters are used in galvanizing processes where molten zinc or other metals are used to coat steel or iron to prevent corrosion. Lead covered heaters can withstand the high temperatures and corrosive nature of the molten metals.

- Chemical Industry: They are used in heating acidic liquids or corrosive chemicals.

- Electroplating: In electroplating processes, these are used to heat chemical solutions used for metal deposition onto surfaces.

Chemical heaters are made of Titanium tube offering excellent corrosion resistance for most plating solutions. Titanium heaters are valued for their exceptional corrosion resistance, high strength-to-weight ratio, and ability to withstand extreme temperatures, making them suitable for a wide range of applications such as highly acidic liquids or electroplating baths. Some common uses of titanium heaters include:

- Medical and Pharmaceutical Industries: Titanium heaters are considered best in medical and pharmaceutical applications maintaining hygiene and corrosive nature of chemicals.

- Semiconductor Manufacturing: Titanium heaters provide consistent thermal performance without contaminating the sensitive semiconductor materials.